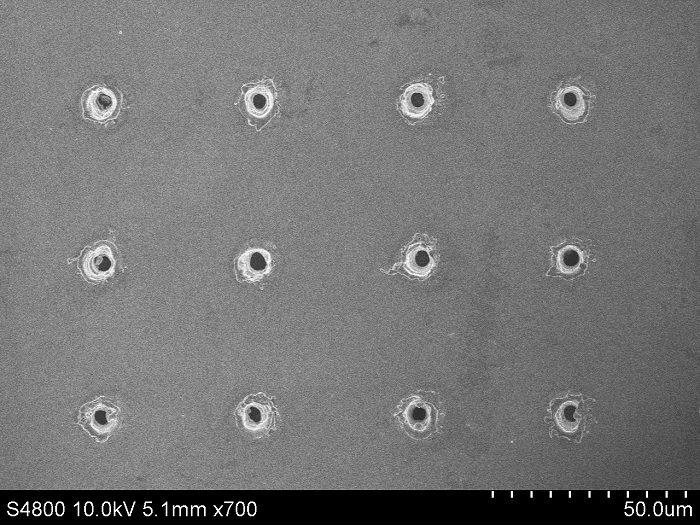

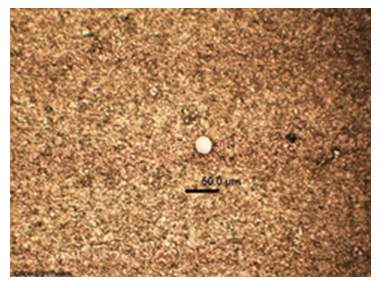

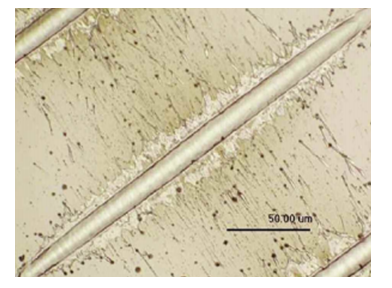

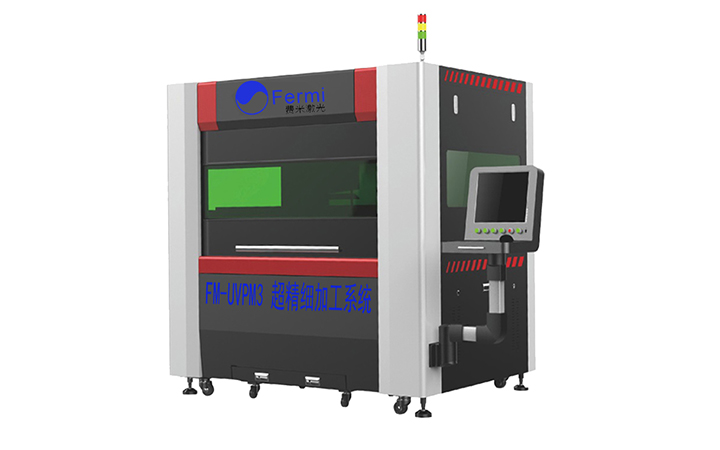

micro drilling ,cutting, engraving and etching metal,ceramics,silicon,glass,organics and so on

Application

flexible circuit board cutting, ITO film etching, micro electronic device manufacturing, printing template preparation, biological chip preparation, precision mold forming.