Pulsed laser instantaneous high-energy melts and vaporizes material, high pressure gas fast blows the melted material, which realizes high speed punching sheet materials with the thickness less than 3mm, such as aluminum, copper, stainless steel, a variety of ceramics and other . Minimum hole size to 0.1mm, excellent hole consistency , smooth cutting, vertical hole wall. By extending the axis of rotation, holes on the tube are proessed.

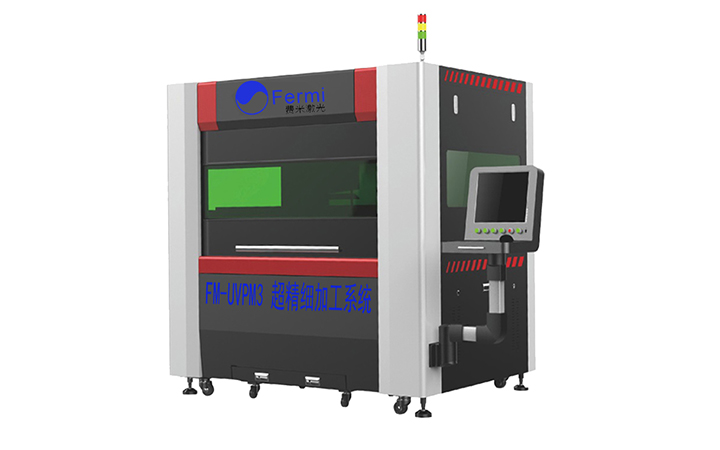

- Product Features

- Product parameter

- Sample Video

- Download

1. Special pulse power supply with high pulse energy stability;

2. High stability of pulse xenon lamp, lighting more than 10 million times;

3. Precision optical path and beam design, to achive good beam quality and excellent spot control;

4. High speed and accuracy worktalbe, Hiwin bar rail and high power Panasonic servo motor drive;

5. Excellent 4 axis control system, excellent machining path optimization and error compensation function,

6. Improve the drilling speed of 10 holes per second or more.

|

Component |

Parameter |

FM-SD500 |

|

Laser |

Wavelength |

1064 |

|

Power |

500W |

|

|

Moldulated frequency |

1~500Hz |

|

|

Beam quality M2 |

<5 |

|

|

Power stablity(8h) |

<3% |

|

|

XY worktable |

Scale |

300*400mm(可定制) |

|

Reposition accuracy |

≤±0.01mm |

|

|

Position accuracy |

≤±0.02mm |

|

|

Acceleration |

≤1G |

|

|

Speed |

≤500mm/s |

|

|

Z axis |

Scale |

150mm |

|

Reposition accuracy |

≤±3μm |

|

|

Position accuracy |

≤±5μm |

|

|

Detection |

CCD Magnification |

40X~100X |

|

Pointing |

Red led 100mW |

|

|

Processing |

Minimum width |

0.1mm |

|

Thickness |

≤3mm |

|

|

Hole Accuracy |

±3μm |

|

|

Reposition accuracy |

≤±5μm |

|

|

Maximum depth width ratio |

>30:1 |

|

|

Material |

metal,ceramics |

|

|

Cooling |

Wtaer cooling |

|

|

Power supply |

380V 50~60Hz 40A |

|

|

Power consumer |

≤15kW |

|

|

Environment |

1~30℃/Non Condensing |

|

Note:Parameters may be changed with the modification,please refer to the quotation.

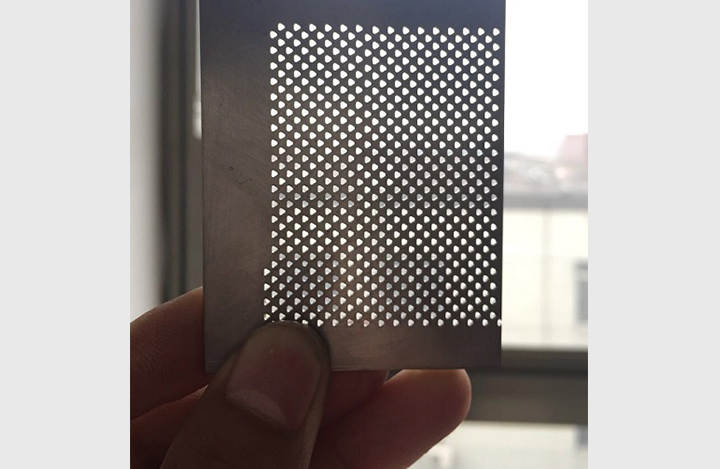

Stainless steel special-shaped hole laser cutting

Vacuum chuck laser drilling 0.3mm

Nozzle laser drilling 0.1mm