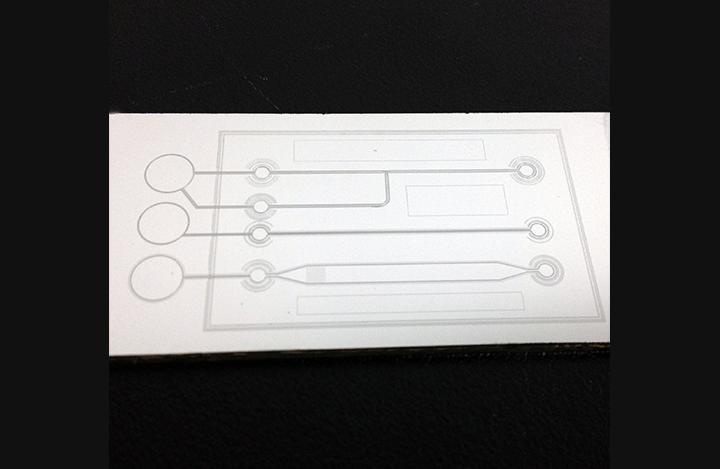

The laser precision etching (or laser precision direct writing) process provided by Fermi laser has the following advantages compared with photoresist etching and so on:

Direct processing and molding, without complex mask manufacturing, coating, photolithography and other processes

No pollution, no consumables, no chemical corrosion

High speed (scanning speed up to 15m / s)

High precision (<± 2 μ m)

There is no material limit, and the base material is glass, ceramics, silicon wafer, organic matter, etc

Minimum processing line width 5 μ M

The processing format can be defined as 300 mm * 300 mm

The laser precision etching direct writing equipment provided by Fermi laser has a minimum processing linewidth of 5 μ m, an overall processing accuracy of ± 2 μ m, a local feature accuracy of less than 2 μ m, and a processing width of 300 * 300 mm. It is used for precision circuit or graphic etching based on glass, sapphire, metal, ceramics, organics, etc.