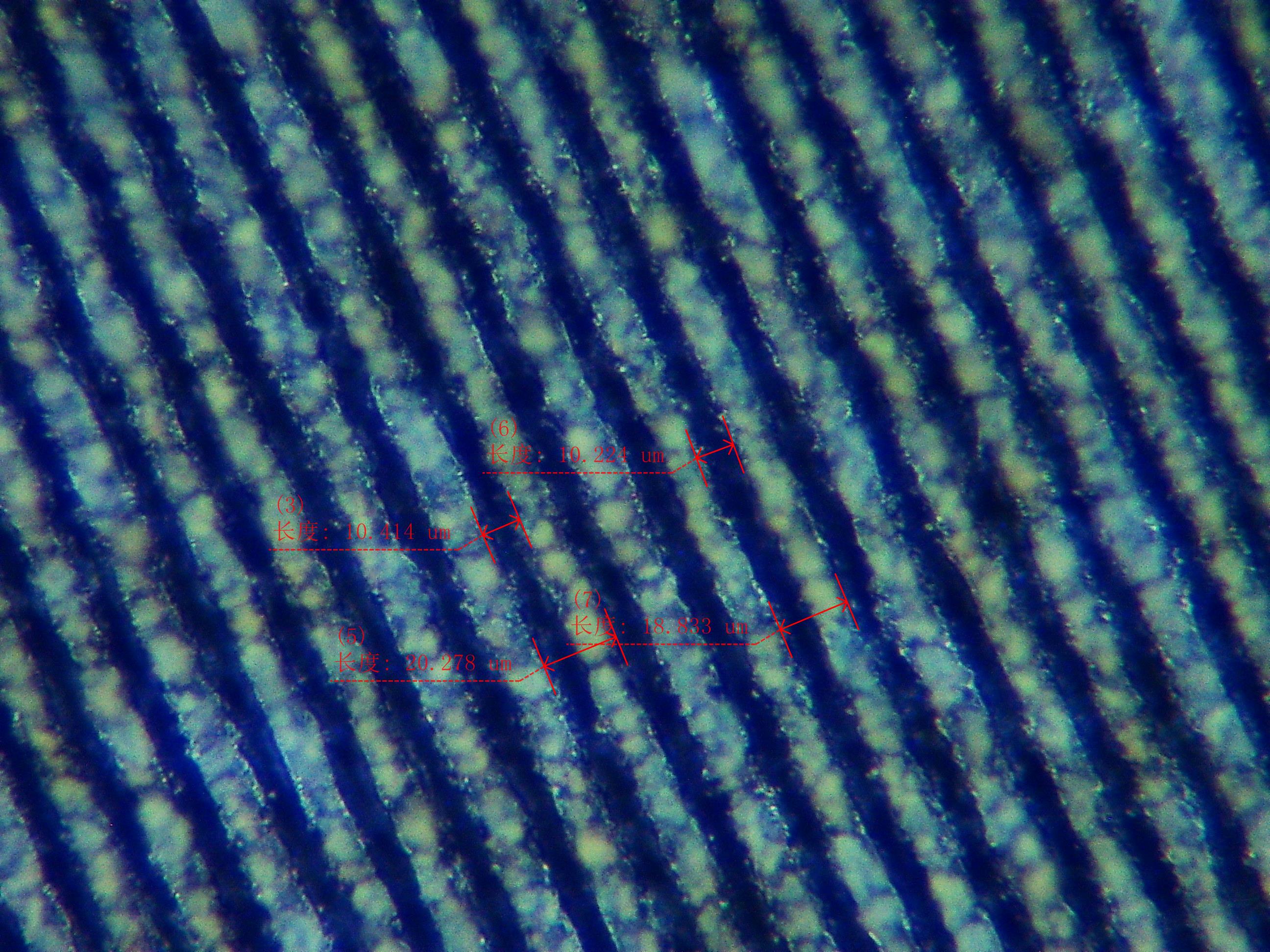

Laser etching of silicon fins: the meter groove is 10 μ m, and the spacing is 10 μ M

Compared with EDM, chemical etching and energy beam machining, laser precision etching has the following advantages:

High speed (up to 10 m / s per second)

High precision (< 2 μ m)

No material restrictions (metals, ceramics, silicon chips, organics, etc.)

Programmable (minimum 3 μ m width, specific width and depth)

The distribution can be customized (processing size is 300 mm * 300 mm), without mold and mask

No pollution and consumables

Direct processing

The laser precision processing equipment provided by Fermi laser has a minimum linewidth of 3 μ m, an overall processing accuracy of ± 2 μ m, a local characteristic accuracy of < 2 μ m, and a processing width of 300 * 300 mm. It is used for precision blind holes, through holes, slotting, cutting and processing of metals, ceramics, silicon chips, glass, organics and other materials.